In the world of manufacturing, precision is everything. High tech engraving machines for tool making have revolutionized the industry, offering unmatched accuracy, speed, and versatility. From crafting intricate designs to ensuring durability, these machines empower businesses to elevate their production standards.

The Power of High-Tech Engraving in Tool Making

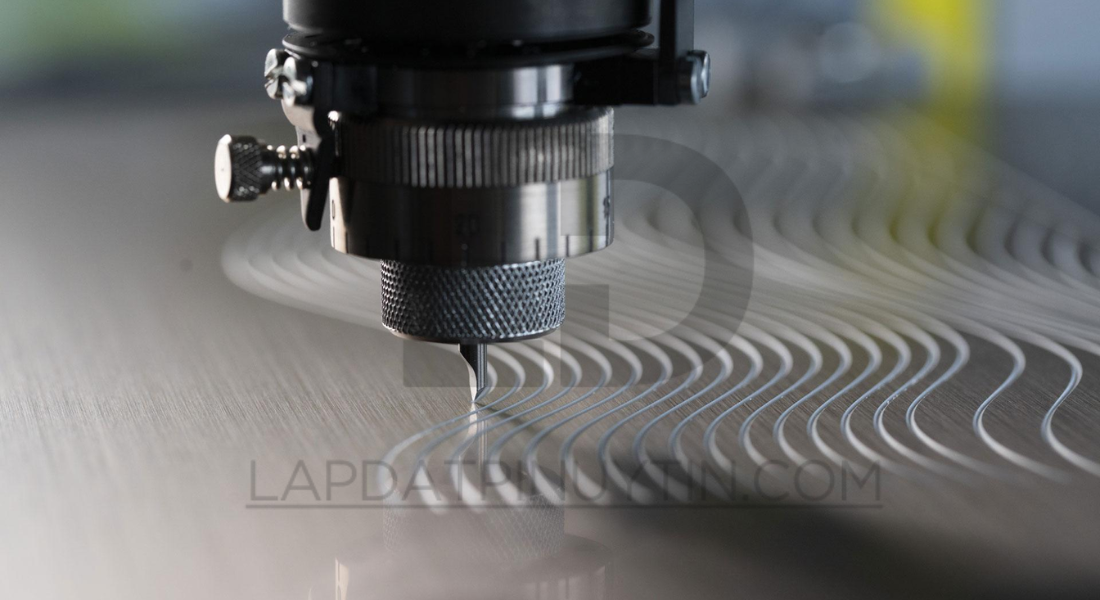

High tech engraving machines for tool making redefine what’s possible in precision engineering. These advanced devices use cutting-edge technology to engrave detailed patterns, logos, and markings on tools and components.

Their ability to deliver consistent results makes them indispensable for industries like aerospace, automotive, and medical manufacturing. With these machines, toolmakers can achieve levels of detail and accuracy that traditional methods can’t match.

Precision That Transforms Production

High tech engraving machines for tool making deliver precision down to microns. This accuracy ensures flawless execution of designs, whether engraving intricate logos or complex patterns.

For toolmakers, precision means reduced waste and higher efficiency. Every piece is engraved perfectly the first time, saving time and resources while ensuring top-quality results.

Advanced Technology for Complex Designs

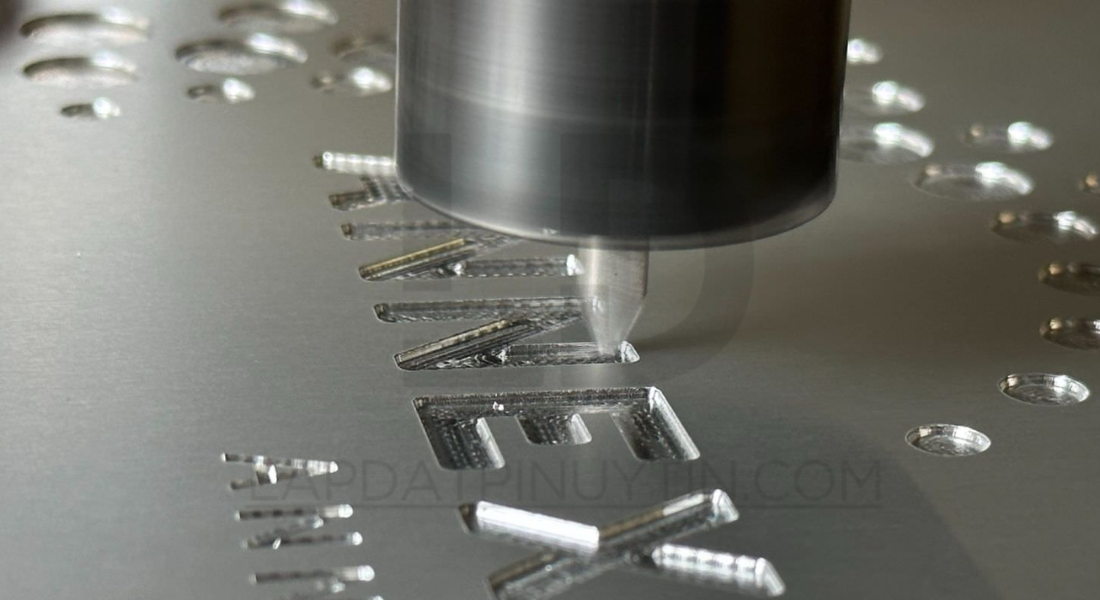

Modern engraving machines use laser or CNC technology to handle intricate designs with ease. High tech engraving machines for tool making excel in creating detailed and complex patterns that require exacting standards.

These capabilities allow manufacturers to meet custom requirements for clients, from personalized tools to specialized components. The versatility of these machines enables endless creative possibilities.

Speed and Efficiency for Large-Scale Projects

Production timelines matter, and high tech engraving machines for tool making are designed to deliver. These machines operate at high speeds, completing engraving tasks in a fraction of the time compared to manual processes.

Their efficiency allows businesses to scale operations without compromising quality. Whether producing hundreds of identical tools or custom orders, these machines handle the workload seamlessly.

Durability Enhanced by Laser Engraving

Laser technology used in high tech engraving machines for tool making creates permanent, wear-resistant marks. These markings withstand extreme conditions, ensuring longevity and durability.

For industries like automotive or aerospace, where tools face rigorous use, this feature guarantees reliability. Permanent markings also improve traceability, vital for quality control and compliance.

Materials Versatility for Diverse Applications

High tech engraving machines for tool making are compatible with a wide range of materials. From hardened steel to lightweight alloys and even plastics, these machines handle them all with ease.

This versatility expands their applications, allowing toolmakers to produce everything from industrial-grade tools to precision medical instruments. Businesses can adapt to market demands without investing in additional equipment.

User-Friendly Interfaces for Streamlined Operation

Operating high tech engraving machines for tool making is simpler than ever. Intuitive interfaces and software make it easy for operators to input designs, adjust settings, and monitor progress.

Automation further streamlines the process, reducing the need for manual intervention. This ease of use increases productivity and ensures consistent results, even for complex projects.

Eco-Friendly Solutions for Modern Manufacturing

Sustainability is a growing priority, and high tech engraving machines for tool making align with eco-conscious practices. Laser engraving, in particular, produces minimal waste and requires no consumables like inks or chemicals.

Energy-efficient designs also reduce power consumption, making these machines an environmentally friendly choice for manufacturers. Businesses can maintain high standards while minimizing their carbon footprint.

Cost-Effectiveness and Long-Term Savings

While the initial investment in high tech engraving machines for tool making may seem significant, their long-term cost savings make them worthwhile. Reduced waste, faster production, and minimal maintenance costs ensure a quick return on investment.

Additionally, their durability and reliability mean fewer replacements or repairs. For manufacturers, these savings translate to greater profitability and a competitive edge in the market.

Enhancing Branding with Custom Engraving

Custom branding is crucial for standing out in competitive industries. High tech engraving machines for tool making allow businesses to engrave logos, serial numbers, and other unique identifiers directly onto tools.

These markings enhance brand visibility while deterring counterfeiting. Customization adds value to products, making them more appealing to customers and clients.

Scalability for Growing Businesses

High tech engraving machines for tool making grow with your business. Their ability to handle both small and large production volumes ensures scalability as demands increase.

For startups or expanding companies, these machines provide the flexibility to take on larger orders without compromising quality or delivery timelines. They adapt to growth, supporting business success.

Meeting Industry Standards with Precision

Industries like aerospace and medical manufacturing require compliance with strict standards. High tech engraving machines for tool making ensure that every marking meets these specifications precisely.

Their ability to produce consistent results guarantees adherence to industry regulations. This reliability builds trust with clients and ensures products meet the highest quality benchmarks.

Real-Time Monitoring and Remote Access

Many modern engraving machines feature advanced monitoring systems and remote access capabilities. Operators can track progress, adjust settings, and troubleshoot issues in real-time, ensuring uninterrupted production.

Remote access also allows for greater flexibility, enabling operators to oversee multiple machines or locations simultaneously. This technology maximizes efficiency and minimizes downtime.

Investing in the Future of Tool Making

High tech engraving machines for tool making represent a leap forward in manufacturing. Their precision, speed, and versatility make them an invaluable asset for businesses aiming to stay ahead in competitive markets.

Investing in these machines means embracing innovation and securing a future of high-quality, efficient production. For toolmakers, the choice is clear—these machines are the foundation of modern manufacturing success.